CPI Products

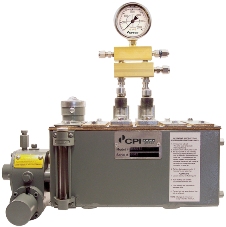

The CPI2012E Pump is designed primarily but not exclusively for the European pump market, the 2012E Pump has been produced with proven pump configurations. Features include heavy duty casting, double ball discharge connector, modular cylinder and suction tube with strainer. Available in box suction, gravity fed and pressure fed models.

CPI Lubricators will accurately deliver a predetermined quantity of oil normally under pressure, at regular intervals to moving parts on all types of industrial machinery. The lubricator consists of a reservoir, drive mechanism, and oil pumps. They are furnished in electric motor drive or shaft driven from the machinery to be lubricated. Shaft driven units can be direct drive, pulley/sheave, or oscillating drive motion.

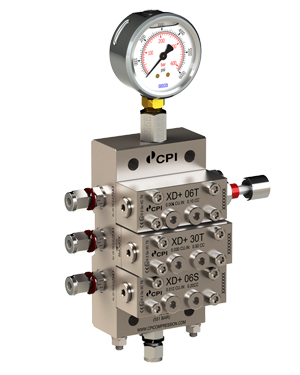

Divider blocks (also known as distribution blocks or divider valves) provided by CPI precisely distribute correct lubrication, reducing the size of lubricator boxes and maximizing lubrication system efficiency. XD+ divider block assemblies consist of three to eight working sections, one inlet section with integral intermediate, intermediate sections for each working block, and one end section with integral intermediate. A single assembly can feed from one (1) to sixteen (16) lubrication points.

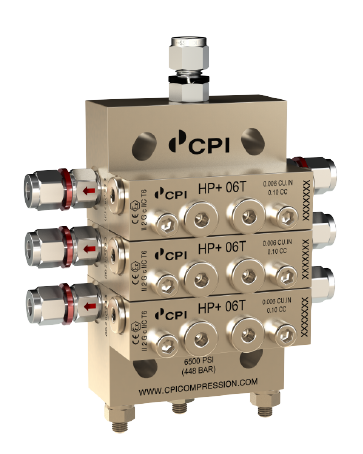

Divider blocks (also known as distribution blocks or divider valves) provided by CPI precisely distribute correct lubrication, reducing the size of lubricator boxes and maximizing lubrication system efficiency. CPI’s HP+ Divider Blocks are a High Performance product line featuring:

•Standard base plate assembly mounts to multiple traditional industry bolt patterns.

•Simplified ordering process to save time and reduce errors.

•Improved performance for applications up to 6500 PSI (448 BAR).

•Improved piston to bore geometry for consistent oil output and longer product life.

•Improved overall sealing with precision CPI Custom 1/8 ORB (O-Ring Boss) port geometry.

•Complete assembly standard with O-ring seals eliminating leakage and need for sealant.

•Each assembly comes standard with Custom ORB inlet tube fitting.

•Improved corrosion resistance with all components nickel plated.

•All base plate assemblies feature internal check valves for added performance protection.

•Standard O-ring seals are VITON® O-Rings (FKM) for improved chemical and heat resistance.

•Each divider block assembly is easily configured to the customer’s specific lubrication needs.

Divider blocks (also known as distribution blocks or divider valves) provided by CPI precisely distribute correct lubrication, reducing the size of lubricator boxes and maximizing lubrication system efficiency. CPI offers the DropsA SMX product line as an affordable performance product featuring:

•Multiple base plate assembly mounting patterns for traditional industry bolt patterns.

•Simplified ordering process to save time and reduce errors.

•Proven performance for applications up to 4000 PSI (276 BAR).

•Base assemblies are bolted together with a threaded insert and attachment screw. This provides no maximum limitation on the number of elements which can be used on the assembly.

•A bypass element is available to accommodate an increase or decrease in lubrication points without disturbing the base assembly or pipe work. This element acts as a blank placehoder and is only used on four section or larger divider block assemblies.

•Each divider block assembly is easily configured to the customer’s specific lubrication needs.

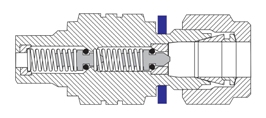

The XDC® checl valve from CPI is a modern redesign of the traditional check valve. Instead of the old fashioned ‘ball’ design, the XDC® check valve uses a self guiding, double poppet with Viton O-Rings. That along with the stainless steel design makes the XDC® check valve the most reliable check valve available today. Additionally, the integral tube connector reduces potential leak paths and makes installation a snap. •Lightweight reduces failure caused by vibration

•Self guiding poppets ensure positive sealing

•8,000 PSI – 400 F

•Integral tube connector eliminates leak path

The CVP® check valve protector installed with the XDC® check valve will eliminate check valve failure caused by heat & gas stream contamination. In addition, these state of the art devices are designed for minimum oil capacity, meaning you get oil to the compressor where its need at startup. Traditional check valve protectors have large capacities meaning that a significant amount of time elapses at startup before oil actually gets to the injection point while the check valve protector ‘fills up’. The minimal design also eliminates fatigue failures from vibration typical of the older and larger check valve protector designs •Provides oil barrier to protect the check valve sealing surfaces from hot gas and trash in the gas stream

•Minimum fill capacity allows immediate delivery of oil to cylinders and packing

•Pressure gauge port enables the operator to visually see when the rod packing is failing.

The Proflo® monitor is 21st Century engineering, utilizing state-of-the-art communication technology and data storage. The unit protects the compressor and end user by monitoring movement of the divider block piston and detecting slow flow and no flow of the fluid flow system. The control housing can be mounted in a control panel or directly to any compressor divider block “Trabon, Lubriquip, SB, Lincoln, Dropsa”. The PF1 operates on field replaceable “AA” Alkaline batteries with expected life of up to 2 years. The LCD indicates when the batteries should be changed. If battery voltage drops below safe operating levels the Proflo® monitor will go into alarm mode and warn the operator of battery failure. Bi-polar wiring allows for simple trouble free wiring to the control panel. The unit incorporates a liquid crystal display to indicate the following: A. Operating time of the compressor. B. “Average”, “Last” and “Current” cycle time of the divider block. C. Total divider block cycles. D. Battery power status. E. Alarm set time for no flow warning. F. Alarm wiring mode: Normally Open/Normally Closed. The cycle time display enables the operator to easily set and monitor pump rates. All trending data and set points are stored in Electrical Erasable Programmable Read Only Memory, (EEPROM). Memory is not lost due to battery failure or change. The PF1 capitalizes on proven technology and components to monitor fluid consumption every 30 minutes, run time of the compressor and trends the operation of the divider block system and oil consumption for 365 days. This device will give the compressor operator a superior product with features never before possible in the industry.

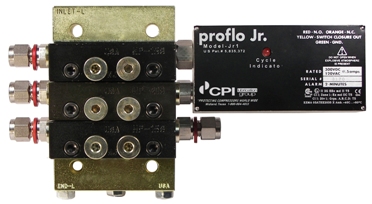

The Proflo® Jr. is a totally enclosed electronic device, combining the latest technology in microprocessor and transistor components for detecting Slow-Flow and No-Flow of divider block lubrication systems. The Proflo® Jr. incorporates an oscillating crystal to accurately monitor the cycle time of the lubrication system to enable precision timed shutdown capability. The magnet assembly and electronics are designed to withstand extreme vibration for compressor applications. The Proflo® Jr. operates on a 3.3 Volt hermetically sealed high temp Lithium battery, with expected life of 10 years. If battery voltage drops below normal operating levels the Proflo® Jr. changes to alarm state and the compressor cannot be restarted. The LED flashes with each divider block cycle to enable the operator to easily set and monitor lubrication rates as recommended by the compressor manufacturer.

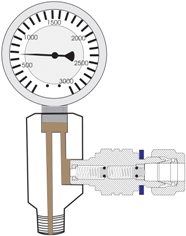

The CPI purge gun provides a convenient, cost effective method to remove all air from the divider block system to ensure all lubrication points will receive lubrication immediately on start-up of the compressor. The manual pump is also an efficient way to troubleshoot the divider block system to locate blockage in divider blocks, tubing lines and cylinder/ packing injection points. The pump delivers full pressure at a minimum stroke for ease of use in tight quarters. All pumps are provided with 36” (914 mm) stainless steel braided hose for long reach applications, 5,000 psi stainless steel liquid filled pressure gauge and chrome-plated steel tube with bullseye sight glass.

Pop Open Pressure Relief: The divider block system is protected from overpressure conditions by the Pop Open Pressure Relief device, or POPR™ valve. This innovative device, only available from CPI, replaces the old style and unreliable rupture discs. When the divider block system over pressures, the POPR™ valve snaps open and diverts the oil to the lubricator reservoir, a closed container, lube pump oil supply line or back to the compressor frame. Unit “always” remains in open position until reset by the compressor operator. Once the system blockage has been fixed, simply reset by closing the POPR™ valve.