Winters Products

•A portable “point and shoot” infrared thermometer that measures remote surface temperatures

•Digital readout (°F or °C)

•Single hand operated

•Uses less than 1 milliwatt of power

•Auto power off feature to conserve battery

•9 volt battery powered

•Fast response time (0.25 seconds)

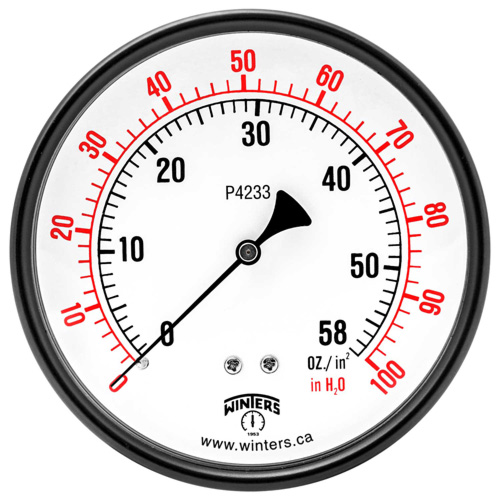

•ASME B40.200 compliant

•Two piece construction and designed to withstand even the most severe process applications

•“Continuous use” seals–backing plate will prevent diaphragm from rupturing if pressure sensing instrument fails. Pressure will be held until instrument is replaced

•Diaphragm is separable for servicing and is available with a 1/8” NPT or 1/4” NPT flushing connection for removing any material which may clog the process connection

•Standard diaphragm is constructed of AISI 316L stainless steel and welded to the upper chamber of the seal for pressures 30 psi (200 kPa) and above; optional Viton® diaphragm available for ranges from 30” Hg Vacuum (-100 kPa) up to 100 psi (690 kPa). Others diaphragms available

•Viton® is highly recommended for applications less than 10 psi

•ASME B40.100 compliant

•RoHS compliant

•CRN registered (all 316 SS only)

•A solar powered digital thermometer that provides a local temperature reading to 1/10 of a degree

•304 stainless steel case, stem and socket

•Hermetically sealed thermometer case

•Minimum required light 35 Lux

•Ceramic resistance sensing element

•1/2” adjustable angle connection

•4” (100mm), 6” (150mm) and 9” (230mm) stem lengths

•°F or °C scales available

•ASME B40.200 compliant

•RoHS compliant

•Type J & K thermocouple sensors offering a wide temperature range; other types available upon request

•Light weight aluminum connection enclosure

•Terminal connections standard

•316 SS sheath material

•IP54 or ATEX rated enclosure available

•Multi-point and surface mount sensors available

•Available with or without 316 SS thermowells

•Excellent flow regulation and leak tight

•The one-piece body construction (no welding) provides strength, safety and corrosion resistance

•“Slow opening” prevents sudden pressure surge and instrument damage

•Materials include carbon steel, carbon steel NACE, stainless steel and stainless steel NACE

•Available in Hard Seat (6,000 and 10,000 psi)

•ASME B1.20.1 compliant

•CRN pending

•Excellent flow regulation and leak tight

•The one-piece body construction (no welding) provides strength, safety and corrosion resistance

•“Slow opening” prevents sudden pressure surge and instrument damage

•Material includes stainless steel and stainless steel NACE

•Available in Hard Seat (6,000 and 10,000 psi)

•ASME B1.20.1 compliant

•CRN pending

•The one-piece body construction (no welding) provides strength and corrosion resistance

•Block & bleed design allows pressure to be bled off without disturbing the permanent piping installation, allowing quick and easy removal of replacement instruments

•Available in Soft Seat (6,000 psi) and Hard Seat (10,000 psi)

•All stems are 316 stainless steel

•CRN pending

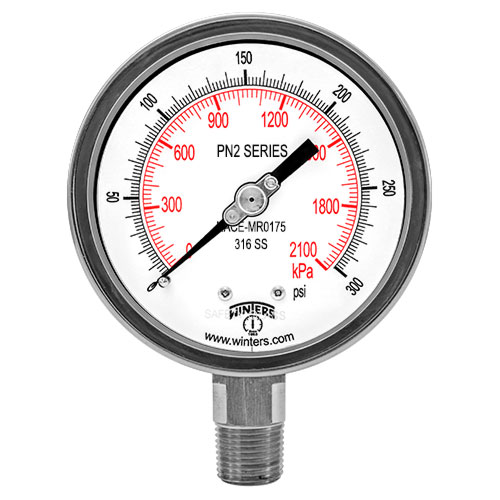

•Liquid filled stainless steel case protects against vibration and pulsation

•Bayonet ring

•Highly accurate

•Back, bottom, or panel mounted

•Under and overload stops

•Ventable plug on 2.5” to 4.5” stainless steel and 4.5″ brass bottom mount and 4″ stainless steel back mount gauges

•Stainless steel or brass wetted parts

•Restrictor screw standard on dual scale (optional on single scale)

•Dry case available

•ASME B40.100 compliant (EN837-1 available)

•RoHS compliant (SS internals only)

•CRN registered

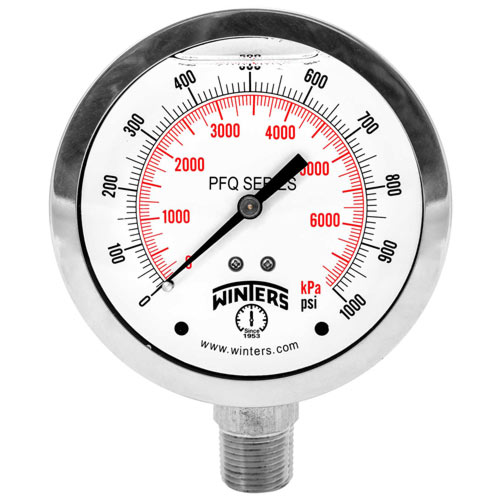

•Liquid filled stainless steel case protects against extreme vibration and pulsation

•Lower back mount with front flange for panel mounting

•Bayonet ring

•Dual and single scale available (psi/kPa & psi only)

•Stainless steel wetted parts

•Restricted orifice standard on dual scale (optional on single scale)

•Safety glass

•ASME B40.100 compliant (EN837-1 available)

•RoHS compliant

•CRN registered

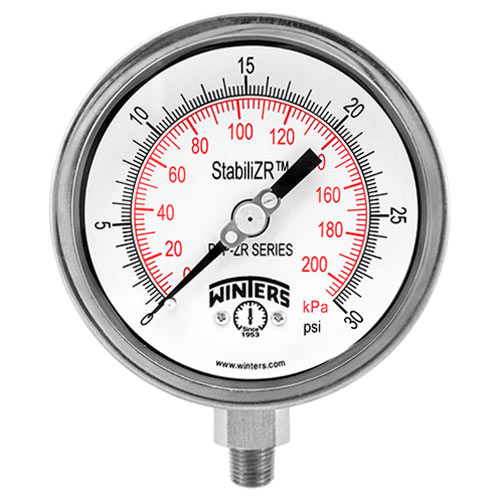

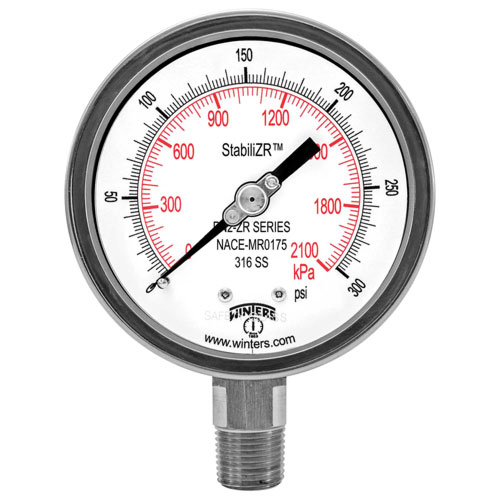

•StabiliZR™ dampened movement minimizes effects of pulsation and vibration without liquid filling

•Restrictor screw standard on dual scale (optional on single scale)

•Stainless steel case

•Under and overload stops

•Back, bottom or panel mounted

•316 SS wetted parts

•ASME B40.100 compliant (EN837-1 available)

•RoHS compliant

•CRN registered

•Pulsation resistant, liquid filled stainless steel case

•Glycerin filled standard

•Brass or lead free brass and stainless steel internals

•Restricted orifice

•Ventable plug on 2.5″ (63mm) and 4″ (100mm) bottom mount (excluding SAE connection)

•Crimp-On bezel

•Single (psi) or dual scale (psi/kPa)/(psi/bar) available

•Optional U-Clamps and front flanges

•Dry case available

•ASME B40.100 compliant

•RoHS compliant (SS internals only)

•CRN registered

•Designed for sour gas applications requiring NACE Standards MR0175-2002 (NACE Standards MR0103-2003 available)

•Glycerin filled case

•Blow out back plug standard

•Under and overload stops

•Wetted parts meet hardness requirements

•ASME B40.100 compliant (EN837-1 compliant)

•RoHS compliant

•CRN registered

•Designed for sour gas applications requiring NACE Standards MR0175-2002 (NACE Standards MR0103-2003 available)

•StabiliZR™ dampened movement minimizes effects of pulsation and vibration without liquid filling

•Blow out back plug standard

•Under and overload stops

•Wetted parts meet hardness requirements

•ASME B40.100 compliant (EN837-1 available)

•RoHS compliant

•CRN registered

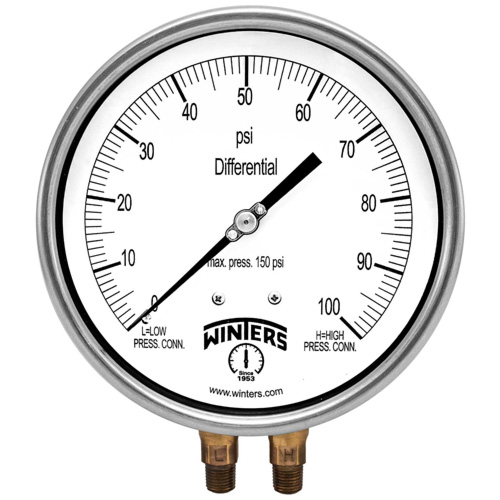

•Designed to measure the wet to wet differential pressures of liquids and gases

•Compact, efficient design available in Low or High psi ranges that facilitates installation in tight spaces

•Low Range housing is constructed of stainless steel and aluminum

•High Range housing is made from a 316-grade stainless steel ideally suited for an industrial environment

•Fast response sensor and signal conditioned electronic circuitry provide quick and accurate readings

•Unique isolation system responds to pressure changes approximately 20 times faster than conventional transmitters with ranges below 100 psi (Low Range model)

•CE approval is standard on all models

•NEMA 4 approval is standard on the Low Range model

•RoHS compliant

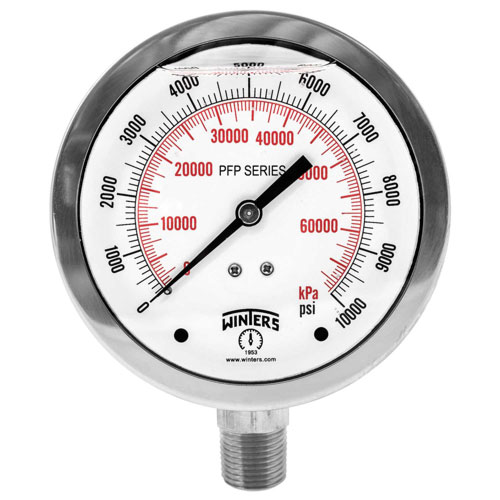

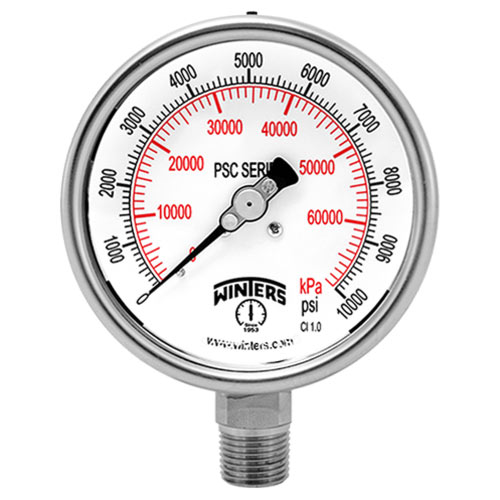

•Solid front blowout back for the ultimate in gauge safety

•Full rotary movement and micrometer pointer for ease in calibration

•Overload stop

•Stainless steel case, socket and internals

•Safety glass lens

•Restrictor orifice standard

•ASME B40.100 (EN837-1 available)

•RoHS compliant

•CRN registered

•Solid front, pressure relief back welded to a 316L stainless steel one-piece diaphragm seal body

•316L stainless steel diaphragm for use on most corrosive media

•Permanently enclosed silicone filled system

•Field-fillable gauge

•Orifice restrictor available for severe pulsation

•Pin stop at 6 o’clock available

•ASME B40.100 compliant

•CRN registered