Murphy by Enovation Controls Products

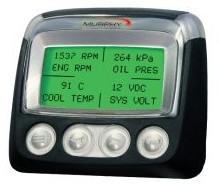

The PowerView 300 Series features robust, multifunctional displays for advanced monitoring of multiple electronic engines. The PV350 display in this series monitors multiple engine and machine parameters on an easy-to-read 3.8-inch (97mm) QVGA monochrome LCD. The display is capable of handling sophisticated engine diagnostics as well as basic engine alarm/shutdown. The PV350 display is customizable using the PowerVision Configuration Studio®, an intuitive tool designed to make personalization simple. Using the software tool, users can tailor basic graphics, designate screen layout and define custom parameters. This panel is equipped with five tactile push buttons to quickly access a convenient menu. In addition, a backlit, heated graphic display and two LEDs indicate active-fault alarm or shutdown status.

Murphy offers two types of diesel fuel line valves: check valves and pressure relief valves. The CKV series check valves are in-line, one-way valves that prevent fuel from being siphoned back into an injector or injection pump which could delay a shutdown. There are two types of check valves: CKV2336 and CKV1WPS. The CKV2336 has a 1/4 NPT threaded male connection on each end for connecting to fuel line fittings or hoses. The CKV1WPS check valve is typically mounted in the fuel bypass line of the last fuel injector. The CKV1WPS features a hollow bolt connection and a barbed, 1/8 NPT connection for flex hose or fitting. The PRV series pressure relief valves, relieve overpressure in a fuel system usually caused by closing of a solenoid fuel valve. The PRV50 and PRV70 have a 1/4 NPT threaded connection on each end for connecting to fuel line fittings or hoses.

The ST Series Selectronic Tattletale annunciators are a simple and inexpensive answer to your remote alarm annunciator needs. Basic models ST5AS and ST10AS are general purpose alarms suitable for a variety of applications. Model ST8 gives first out annunciation of fault. Model STA16 is designed for generator set applications and can be configured to meet NFPA requirements for standby generators. These compact Tattletale annunciators tell you by a flashing LED which variable malfunctioned. Many feature a pulsating Mini-Siren to audibly alert you to the malfunction. The audible alarm is silenced by depressing the Alarm Silence push button, but the visual signal remains in operation until the fault is corrected and the contacts are cleared. A test push button allows you to test all alarm LEDs. Because LEDs are solid state, cold light, electronic devices, they don’t burn out as incandescent light bulbs do. Basic models accept 8-32 VAC or 8-40 VDC input voltage. Others are available for either 12 VDC or 24 VDC input. Preprinted peel and stick nameplates for common faults are supplied with each unit. Most of the Selectronic Tattletale annunciators accept either normally open (N.O.) or normally closed (N.C.) contacts. You can mix N.O. and N.C. contacts on the same unit. All models except STA16 have a time delay available to lockout the audible alarm on startup.

The PSB switch is a direct-mount switch for critical pressure points. It has one limit contact that can be used to activate an alarm, actuate indicator lights or shutdown equipment. The construction of this instrument is the same as Murphy’s time-proven Swichgage® instrument. A precision machined brass mounting plate and port captures a high-quality, stamped beryllium copper diaphragm. The single-pole, double-throw (SPDT) snap-switch is operated directly from the diaphragm for quick acting and positive switching. Trip point is factory preset according to your specifications. Housing is weather sealed to prevent entry of moisture, dust, etc. A glass-filled nylon terminal block with screw terminal connections gives the PSB switch a real advantage in industrial engine applications. The PSB is ideal when reading is not desired, but pressure is critical to operational efficiency. Intended for use in general purpose non-classified areas.

The MPI Detonation Sensing Interface System utilizes a pair of highly sensitive accelerometers to detect detonation. In the event of detonation the DSI signals the MPI Control System, via 4/20 ma control signal, which responds by immediately retarding the timing thus eliminating the potentially harmful effects of continuous detonation.

The PowerView PVM Series Gages are intelligent gages designed to display easy-to-read information transmitted by PowerView. The PVM gages communicate with PowerView via a single RS485 twisted pair MODBUS RTU serial link. The gages can be daisy-chained using quick-connect harnesses. The major feature of the PVM gage is its balance between design and functionality. These modern gages offer a selection of lens and bezel styles and colors. The PVM gages also include features such as a smooth stepper motor operation for the 270° sweep pointer, an environmentally sealed case with two Amp Mini Universal Mate-N-Lok connectors molded into the casing, and green LED backlighting. They are available for standard 2-1/6” (52mm) and 3-3/8” (86mm) diameter hole sizes. Their plastic cases incorporate a D shape allowing panel cutouts that eliminate gage rotation during installation.

The PowerView Analog Gages (PVA) are a series of intelligent gages designed to display easy-to-read information transmitted by the PowerView. The PVA gages communicate with the PowerView via a single RS485 twisted pair MODBUS RTU serial link. The gages can be daisy-chained using quick-connect harnesses with watertight connectors. The major feature of the PVA gages is its balance between design and functionality. These modern gages offer a selection of lens and bezel styles and colors. The PVA gages also include features such as a smooth stepper motor operation for the 270-degree sweep pointer, an environmentally sealed case with two Deutsch DT style connectors molded into the case and green LED backlighting. They are available for standard 2-1/6-inch (52mm) and 3-3/8-inch (86mm) diameter mounting hole sizes. In addition, the polycarbonate/polyester alloy cases incorporate a D shape allowing panel cutouts that eliminate gage rotation during installation. The PowerView Audible Alarm (PVAA) alerts operators to fault conditions via piezoelectric alarm and relay contacts. It also has a temporary silencer button that silences the audible tone for two minutes on warnings and 30 seconds on shutdown conditions. All PowerView gages can be powered by 12- or 24-VDC systems.

The PowerView CAN Gages (PVCAN) are a series of intelligent gages designed to display easy-to-read information broadcast over the SAE J1939 communications. These gages are designed to be wired directly to the J1939 CAN bus without the need of another device driving them. The PVCAN gage includes features such as a smooth stepper motor operation for the 270-degree sweep pointer, an environmentally sealed case with two Deutsch DT style connectors molded into the case and green LED backlighting. They are available for standard 2 1/6-inch (52mm) and 3 3/8-inch (86mm) diameter hole sizes. In addition, its polycarbonate/polyester alloy cases incorporate a D shape allowing panel cutouts that eliminate gage rotation during installation. All PowerView gages can be powered by 12- or 24-VDC systems.

The HelmView HVS450 is specifically designed to meet the engine monitoring needs of the Commercial Marine industry. Its durable design and easy to use interface offers a complete view of your vessels engines. Monitor propulsion, auxiliary, transmission, and genset engines all on one display. It is equipped with the ability to switch between Day and Night mode operations and even has a blackout option. There are multiple screens to choose from and the ability to turn screens on/off to meet your specific marine application needs. The HVS450 has the ability to be connected to a video camera for monitoring the engine room or other important areas of the vessel. This multi-functional display allows you to monitor multiple engines, transmissions, fuel usage, and more using only one device, thus greatly reducing operating costs. It has eight tactile push buttons that can easily be pressed with or without gloves. The HVS450’s sunlight viewable, full-color screen makes seeing life-like gauges, alarm warnings, service codes, and video easy to view in virtually any condition. The HVS450 is fully programmed to display Diagnostic Trouble Codes showing critical alarms and text explanations. The HVS450 display is compatible with the PowerVision Configuration Studio® so custom software configurations can be quickly developed. With the PowerVision Configuration Studio it is easy to define the user interface screens, monitoring requirements and specifications that are unique to the Commercial Marine industry. The HVS450 paired with the PowerVision Configuration Studio extends custom configuration from only monitoring to equipment control, data logging, and additional alarming. You can even add custom graphics and company branding to the user interface.

The PowerView 25 is an engine and diagnostic display in an economical, compact package. This J1939-compliant device provides electronic engine parameter data, is simple to install, matches the PowerView line of rugged displays and can be powered by 12-volt or 24-volt systems. The PV25 is equipped with two push buttons to quickly access a convenient menu. In addition, a back-lit graphic display and two LEDs indicate Active-fault Alarm or Shutdown status. Active and Stored Fault messages display the SPN (Suspect Parameter Number), FMI (Failure Mode Indicator) and the OC (Occurrence Count) using the SAE J1939 protocol. The PV25 displays up to 20 standard J1939 parameters in standard or metric units. The following are some of the engine parameters of the PV25 displays:

•Engine RPM

•Engine Oil Pressure

•Engine Hours

•Coolant Temperature

•ITA/Stage IIIB Parameters

•Active Service Codes

•System Voltage

•Stored Service Codes

The PowerView PV101 display is a multifunction tool that enables equipment operators to view standard engine and transmission parameters and active/stored trouble codes. The display can show a single or a fourparameter simultaneous display with text descriptions for most common fault conditions. The enhanced alarm indicators have ultra-bright alarm and shutdown LEDs. The PV101-C and PV101-A have many features including:

•Tier 3/Euro Stage III and earlier (PV101-A)

•Tier 4/Euro Stage IV (PV101-C) – Three icons indicating Active Regeneration, Inhibit Regeneration and Diesel Particulate Filter DPF Restricted. Menu offers Auto DPF Regen and Request DPF Regen.

•OEM Menu – A password protected menu offers access to MODBUS Setup, Engine Speed Control ON/OFF and other critical menu items that require restricted access.

•TSC1 (Torque Speed Control) (PV101-C only) – Allows users to set run speed via CAN if supported by engine manufacturer

•Additional 4-Up Screen (PV101-C only) – Allows user to have two 4-Up screens to toggle between. Second user configurable screen is defaulted to show Tier 4 Parameters: DEF Level (Diesel Exhaust Fluid Level), DPF Active Regen Status, Exhaust Filter Outlet Temp and Exhaust Filter Inlet Temp.

•Multiple language options − English, Spanish, German, Italian, French, Brazilian Portuguese, Chinese, Japanese, Czech and Russian

•Sender Input − Select between backlight dimmer function or fuel level. Can be calibrated to use non-Murphy fuel senders.

•Service Reminders – Five service reminders allow users to set hours for: Change Engine Oil, Air Filters, Hydraulic Oil, and Service Engine and Service Machine.

•Select Source Address – Select the exact address the PV101 will claim on the bus

•The ability to select CAN bus Data Rate

•PV101-C Configuration Tool (PV101-C only) – PC tool allows users to create, view, edit and download configurations for the PV101

•The PV101-C Display Gages – Compatible with PVA and PVM gages as well as additional J1939 I/O modules

•Displays more than 50 standard SAE J1939 parameters

•Shows helpful troubleshooting description for the supported parameters. Shows SPN, FMI and OC for all faults

The PowerView 300 Series features robust, multifunction displays for advanced monitoring of multiple electronic engines. It’s capable of monitoring multiple engines and machine parameters on an easyto-read 3.8-inch (97mm) QVGA monochrome LCD. The display is capable of handling sophisticated engine diagnostics as well as basic engine alarm/shutdown. Customize the PV380 display using the PowerVision Configuration Studio®, an intuitive tool designed to make customization simple. Using the software tool, users can tailor basic graphics, designate screen layout and define custom parameters. The PV380 is equipped with five tactile push buttons to quickly access a convenient menu. In addition, a backlit and heated graphic display with LEDs indicate alarm or shutdown status.

The PowerView 450 display features a freely configurable design allowing custom software to be quickly developed. The display is compatible with PowerVision Configuration Studio® software to enable quick and easy changes to the programming. The highly durable display features a full-color, robust 4.3-inch bonded LCD for best-in-class sunlight readability. The PV450’s rugged design makes it a great solution for all types of environments and applications.

The PowerView 780 display is a full-featured, configurable display that shows integrated engine, transmission and diagnostic information in an easy-to-read operator interface. Equipment functionality can be further integrated through the available I/O and controlled via the CAN bus. The PV780 features a full-color, 7-inch bonded LCD for brighter, smoother graphics and best-in-class sunlight readability. The rugged design makes this display a great solution for extreme environments. The PV780 display is compatible with PowerVision Configuration Studio® which allows users to edit CAN parameters, add OEM branding and create custom equipment screens for a unique and sophisticated user interface.

With software and hardware designed to fit with the existing PowerView® line of displays, ICE takes the functionality of stereo and multi-functional displays and brings them to the recreational marine market. ICE software features the standard radio and stereo functions expected, but it also allows for Bluetooth connectivity that allows hands-free notifications on the display for new texts, missed and incoming calls, signal strength, battery life and BT connection status. The software also offers audio profiles, four zone control, five-band EQ and customizable sound control. By giving users the ability to synch their smartphone, ICE brings car-like features designed to withstand the marine environment. ICE’s versatile internal sources include AM tuner, weather band, digital FM tuner with RDS, title tagging, Bluetooth audio, a variety of inputs and high-quality audio features that include remote control capabilities. The single intuitive interface easily guides users through menus so they do not feel like they are relearning the system each time they use it. ICE processors can easily handle upgrades to keep up with the ever-changing need for customization and growth in technology. This incredibly flexible solution can also be used as a standalone feature in many other applications.

External power is required to make the PVM gage line compatible with existing MurphyLink products, such as PV1000, Cascade, iGuard and eGuard. The PVS-5 power supply device supplies 5 volts of external power and load dump protection for up to 6 PVM gages. The maximum length of the power and data connection between gages is 0.5 meters (8.5 meters total).

SenderCAN is a compact, encapsulated input & output module for J1939 CANbus systems. SenderCAN allows the integration of analogue and digital measurement, control and indicating devices into modern CAN and ECU-based engines and systems. SenderCAN has up to four inputs and two outputs, each of which is factory configured to OEM requirements. Inputs can be set for use with resistive sender or switch signals, which are translated into J1939 CANbus messages with appropriate PGN address, data scaling and transmission rate. Outputs can be configured to drive gauges, lamps, relays or other control devices, based on received J1939 data. Standard versions are available for use with common senders (e.g. FuelCAN™ model FLC300 for fuel level senders), but SenderCAN is primarily intended for OEM-specified input, output and CANbus requirements. Please note that minimum order quantities or charges apply for custom solutions. SenderCAN is compact and light enough for inclusion in many wiring harnesses, but can also be surface mounted via four fixing holes. The case is fully sealed in epoxy resin for high impact and environmental resistance.

The FuelCAN is a compact interface that translates fuel level sender signals into SAE J1939 CAN bus messages. The device allows integration of standard senders into modern J1939/CAN bus engine instrument and control systems. FuelCAN modules have three inputs (only one of which is connected at any one time): input 1 is configured for use with Murphy ES series resistive fuel level senders; inputs 2 and 3 can be used with fuel level senders having compatible resistance ranges as shown below. FuelCAN inputs can also be factory configured for use with other types of fuel level or resistive senders. FuelCAN is compact and light enough to be incorporated into most wiring harnesses but can also be surface mounted. The polycarbonate case is fully sealed in epoxy resin for high impact and environmental resistance. A rear facing LED indicates input/CAN bus status.

The MeCAN™ is a compact, encapsulated interface module that translates resistive sender, fault switch and speed signals into SAE J1939 CAN bus data. MeCAN allows quick and simple integration of mechanical engines into modern CAN bus systems. Applications include the retrofit of older engine fleets with modern digital instruments, controls and telemetry, engine hour tracking and the development of standard control panels for mechanical engines. MeCAN has three sensor inputs and one output. Two inputs are for oil pressure and coolant temperature sensing, either by fault switches or resistive senders. The third input measures engine speed using a magnetic pickup or charge alternator signal. Input signals are translated into SAE J1939 CAN bus messages with assigned PGN address, data scaling and transmission rate. The output can drive an alarm lamp or buzzer or actuate a shut-down relay if the pressure, temperature or speed inputs deviate outside preset fault limits. A fourth input is connected to a speed calibration potentiometer during set-up mode only. DIP switches allow selection of normal/set up mode and two speed input ranges. An LED gives indication of operating mode and CAN bus activity. MeCAN is compact and light enough for inclusion in engine wiring harnesses but can also be surface mounted. The case is fully sealed in epoxy resin for high impact and environmental resistance. Two standard versions allow use with either fault switches or Murphy ES series resistive senders. Custom solutions are also available for non-standard, volume OEM requirements.

As part of the MurphyLink® family, CANdrive offers a cost-effective instrument solution for modern electronic engines. CANdrive modules read engine ECU CAN bus/J1939 data, drive standard electric panel gages and provide LED indication of status and faults. CANdrive has three dedicated outputs for tachometer, oil pressure and coolant temperature gages, with DIP switch selectable compatibility for Murphy, VDO or Datcon gages. For volume orders, the outputs can be custom configured for other gage types, lamps, relays or remote signaling. CANdrive advantages include: the retrofitting of existing electric gage panels to new J1939 compatible engines

•the use of standard, economical electric gages with new J1939 engines

•no need for installation of additional gage senders, tachometer magnetic pickups and wiring.

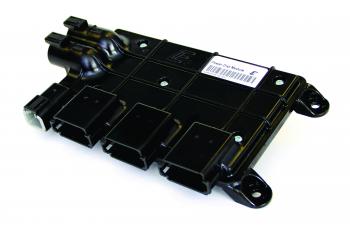

The XM500 Module is a configurable Input/Output (I/O) module designed to bring analog and digital inputs and output onto the SAE J1939 CAN. The XM500 configuration tool provides a user-friendly interface allowing the user to create or change the configuration used on the XM500 module. Your application may require monitoring of other information which may not be provided by the OEM engine or transmission electronic control unit (ECU), such as fuel level, hydraulic oil pressure or a low engine coolant level switch. The XM500 is ideally suited to bring the additional information you need onto the J1939 CAN Bus and can be configured to broadcast fault codes and activate digital outputs per input condition such as fuel level low, hydraulic oil temperature high, etc. Because the XM500 broadcasts information using the J1939 standard protocol, the information can be displayed using standard J1939 display modules, such as the PowerView PV101.

The Murphy PowerCore® Intelligent Xpansion™ Power Distribution Module (PDM) expands CAN bus control networks by replacing existing relay and fuse boxes with more reliable solid-state switches that can directly drive work lights, wiper motors, cooling fans, directional DC motors and other high current loads. Each of the 12 IX3212 outputs can switch or proportionally control up to 15 A loads in 2.5 A increments and feature built-in over-current detection and shut-down capability. Outputs are paired to run up to six electric motors with H-bridge direction control. Twelve digital inputs monitor switched battery, ground and floating inputs. Additionally, eight analog inputs are available with a 5V sensor supply. Wiring length is reduced and costs are cut by remotely locating the IX module near loads and signals. The I/O is multiplexed using a CAN bus network which allows engineers to greatly simplify harness design for ease of installation and improved reliability. For applications not requiring a CAN bus controller, the inputs can directly trigger the outputs so there is no need for a separate controller.

The SV-series valve is a normally closed valve that opens when current is supplied from the battery through a magnetic switch. Temperature, level, or pressure SWICHGAGE® instruments installed on the engine and pump or compressor, trip the magnetic switch, breaking the circuit from the battery which closes the valve and stops the engine. The SV-12 valve operates on 12VDC, has a 1/4 NPT inlet and outlet, and a full 3/16 in. (5 mm) orifice. 24 VDC (SV-24) is optional The SV valves open against 30 psi. (207 kPa) [2.07 bar] inlet pressure.