FW Murphy Products

Optimizing your engine’s performance and maintaining emission compliance is easier than ever with Murphy’s new Engine Integrated Control System (EICS). It is a complete integration package pre-calibrated specifically for your engine model. EICS combines key components – ignition system (powered by Murphy’s IntelliSpark™ Ignition technology), air/fuel control, speed governing, interface and diagnostics, sensors, harnesses, catalyst and engine control unit (ECU) – in one package, saving you money and man-hours associated with the installation and setup of separate engine components. The EICS has been pre-configured for your convenience, ensuring your engine will run at optimum performance without the need for manual field adjustments. Its D-EPR valve accommodates wide variations in fuel composition and speed/load ranges, maintaining efficiency with load following technology for even the toughest gas lift applications. In addition, the EICS eliminates the need for pretest site visits by maintaining emissions – saving you time and money. With EICS you can be certain your site will pass required testing, like Quad J testing, without the need for pretesting to get dialed in.

These fuel shutoff valves are semi-automatic devices for shutdown of natural gas fueled engines. The valve is opened manually and closes when the electromagnet is energized and trips the latch. The valve can be closed manually by turning the valve’s disconnect knob. A normally energized model is available that holds the valve open electrically and closes when the coil is de-energized. A vent in the valve body relieves trapped gas when the valve closes. A pop-out indicator button informs you when the valve is open or closed. The valve’s tripping power is provided by an engine ignition system or battery. Models are available for magneto, CD ignition or 12/24 V battery.

TATTLETALE® annunciators and Magnetic Switches are the nerve centers that translate SWICHGAGE® contact operations into decisions and operate the alarm or shutdown device. They are the electrical load carrying devices for the alarm or shutdown device. TATTLETALE® annunciators indicate which monitored function failed leading to the alarm or shutdown whereas magnetic switches do not. Magnetic switches operate basically as a latching relay.

The PD8100 Series eliminates pointer flutter on pressure indicating Swichgage® devices which are subject to pulsating pressure from reciprocating pumps or compressors. It also allows a close setting of high and low contact points providing for more accurate pressure indication and control of equipment. The PD8100 Series decreases wear on geared movements and increases the life of pressure indicating instruments by eliminating excessive gage strain and unnecessary movement, a necessity which quickly pays for itself by protecting any pressure indicating and control instrument which is subject to pulsation.

The PXT-K Series pressure transmitters are state-of-the-art instruments providing 4-20 mA output. Each Piezoresistive Pressure Transmitter contains a transducer comprised of a piezoresistive silicon chip mounted on a glass-metal feed-through header welded into a stainless steel housing and filled with silicone oil. The very thin laser-welded stainless steel isolation-diaphragm completes the front side. Media pressure is transferred from the stainless steel isolation-diaphragm via the oil inside the cell to the silicon measuring chip. This construction, combined with the advanced internal signal conditioning circuitry, results in a rugged instrument with extremely small temperature error and class-leading EMI/RFI resistance.

The ignition coil is one of the most critical components of any ignition system. When properly matched to the ignition controller’s output, the ignition coil ensures optimum performance and reliability. Our Smart Coil™ instruments are patented, and are used with IntelliSpark® Control Technology to provide real time diagnostics and prognostics. Also offered are coils for direct replacement of Altronic coils. All Murphy coils are manufactured with the highest quality of construction for long life durability.

The IntelliSpark® 32/16/8 series ignition systems are capacitive discharge, low-tension type designs. The system is capable of generating precise spark timing that improves fuel economy, load balance and ignition stability. The controller design incorporates a state-of-the-art, 16-bit, microcontroller. This technology provides users with a highly flexible solution to meet their ignition needs. The user can choose from one of five methods of crankshaft sensing for a 4-stroke engine and two methods for a 2-stroke engine. The Murphy ignition coils used with this controller are “smart coils” with a sense lead connection for spark plug demand voltage measurements allowing the system to: Measure demand on each cylinder’s plug for diagnostic purposes.

•Automatically control the energy delivered to the smart coils to optimize spark plug life.

•Use the measured demand in the unique “camless” crank method to determine the compression stroke, eliminatingthe need for a camshaft sensor.

Several smart coil designs are available to accommodate specific ignition requirements including, remote mount coils and plug-mounted (integral) coils, non-hazardous or CSA C1, D2 rated versions. This system also includes the Murphy PV-450 full color screen display for control functions, monitoring, programming, and diagnostic testing. The 8 button display includes comprehensive built-in help files and wiring information for the coil harness and a data base of common engines for ease of configuration.

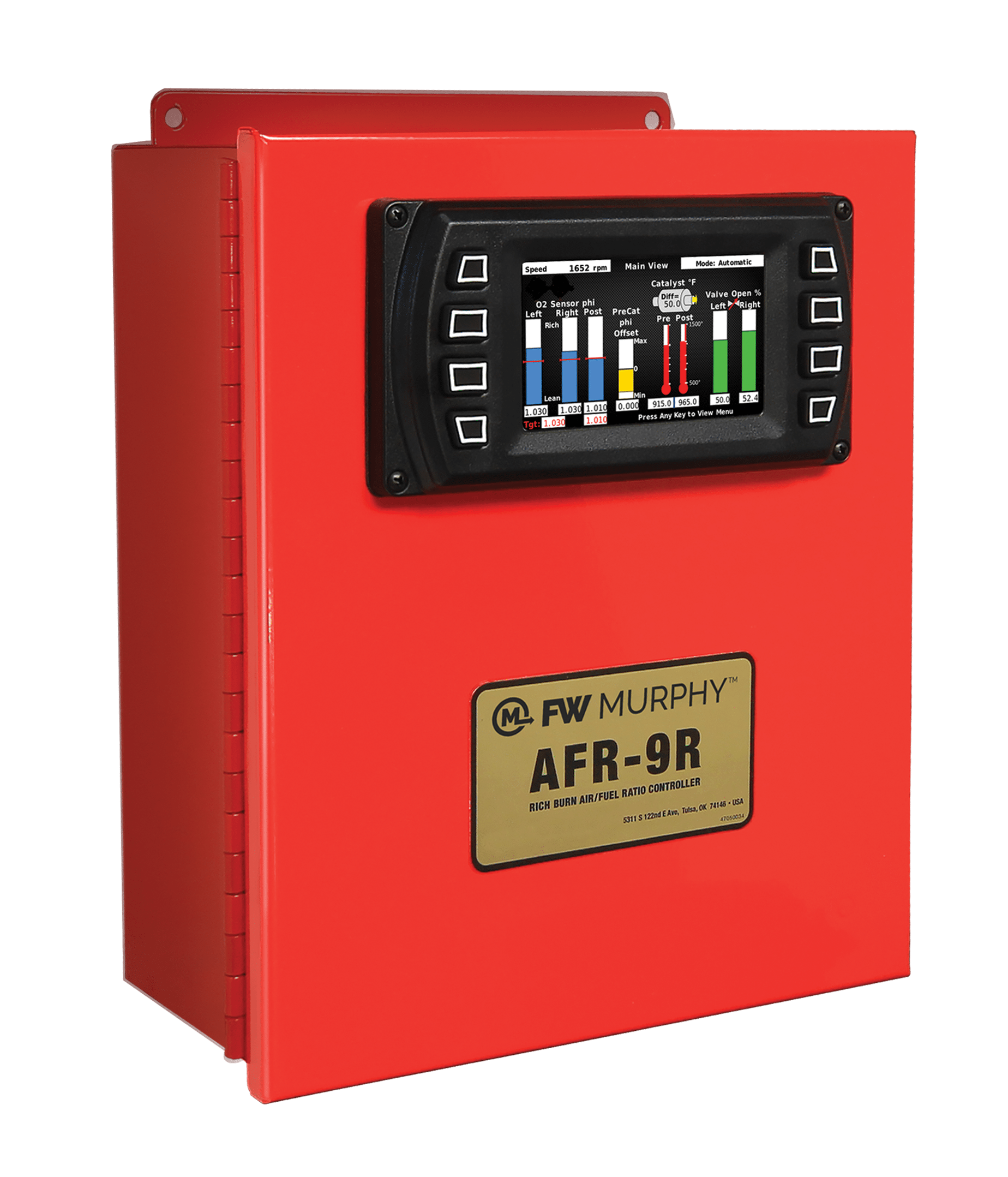

Compliance Controls AFR-9R air/fuel ratio controller offers the same simplicity as the AFR-1R model. Non-intrusive installation. Streamlined menu-driven navigation. But with more setpoints, you get even tighter control. The AFR-9R controller offers nine setpoint targets, based on a combination of three RPM settings and three manifold pressure settings. As your engines load conditions change, your AFR-9R continues to make sure it is in the best possible operating range. It also includes manifold pressure and RPM sensing technology. If your site is facing tightening regulations, changes in ambient temperature, big load swings or gas quality/pressure changes, the AFR-9R is the right choice. It’s simple air/fuel ratio control with more flexibility.

The AFR-64R controls rich-burn, natural gas-fueled engines – maximizing the efficiency of a three-way catalyst by maintaining the proper air-fuel ratio over varying engine loads, speeds, fuel quality, ambient temperatures and barometric pressures. And the AFR-64R works without operator intervention. Easy to install, even easier to use, and equipped with a comprehensive 44-fault on-board diagnostics and troubleshooting system, the Windows-based AFR-64R redefines the state-of-the-art – in hardware, microprocessor power, control system software, operator interface options, adaptability to variable engine conditions, software upgradeability, you name it.

The AFR-64L Lean-Burn Air-Fuel Control System was engineered specifically for lean-burn, spark-ignited natural gas engines. It minimizes engine emissions, maximizes fuel efficiency, and cuts engine maintenance costs – by maintaining the proper air-fuel ratio over varying engine loads, speeds, fuel quality, ambient temperatures and barometric pressures. And the AFR-64L works without operator intervention. Easy to install, even easier to use, and equipped with a comprehensive 44-fault on-board diagnostics and troubleshooting system, the Windows-based AFR-64L redefines the state-of-the-art – in hardware, microprocessor power, control system software, operator interface options, fast response to varying engine conditions, software upgradeability, you name it.

Striking the right air-fuel ratio to support your catalytic converter shouldn’t be that hard. And it’s not — if you choose the right equipment. Compliance Controls’ AFR-1R air-fuel ratio controller is exactly the right choice. It’s pure simplicity at every step — from installation to operation. How simple is it? It doesnt get any simpler. Or any smarter.

•Non-intrusive installation — The AFR-1R operates on an auxiliary fuel line, which can be easily isolated for maintenance, analysis or troubleshooting. SIMPLE!

•Single setpoint — No fine-tuning or tweaking needed. SIMPLE!

•Streamlined navigation — Single-button access to the main functions. SIMPLE! The AFR-1R air-fuel ratio control system is the simplest controller of its type on the market. Enter a single setpoint target, and the system starts controlling the air-fuel mix. This system was designed for pure simplicity.

The MurphyLinkTM gages are a series of instruments designed to display information transmitted by the Murphy Display and Diagnostic Module (MDDM) in a traditional analog format. Communication from the MDDM to these units is via an RS485 twisted pair proprietary serial link. The MurphyLinkTM components are environmentally sealed, LED back lit (green) and are available in a standard 2 in. (51 mm) diameter, plastic case, MLA20 Series, (metal case for the audible alarm MLAA20 models). The MLA35 Series Tachometer or Speedometer have a 3-3/8 in. (86 mm) in diameter, plastic case. The MurphyLinkTM gages can be powered by 12 or 24 VDC systems. For 24 VDC systems an MLVC2412 voltage regulator is required for back light power supply.

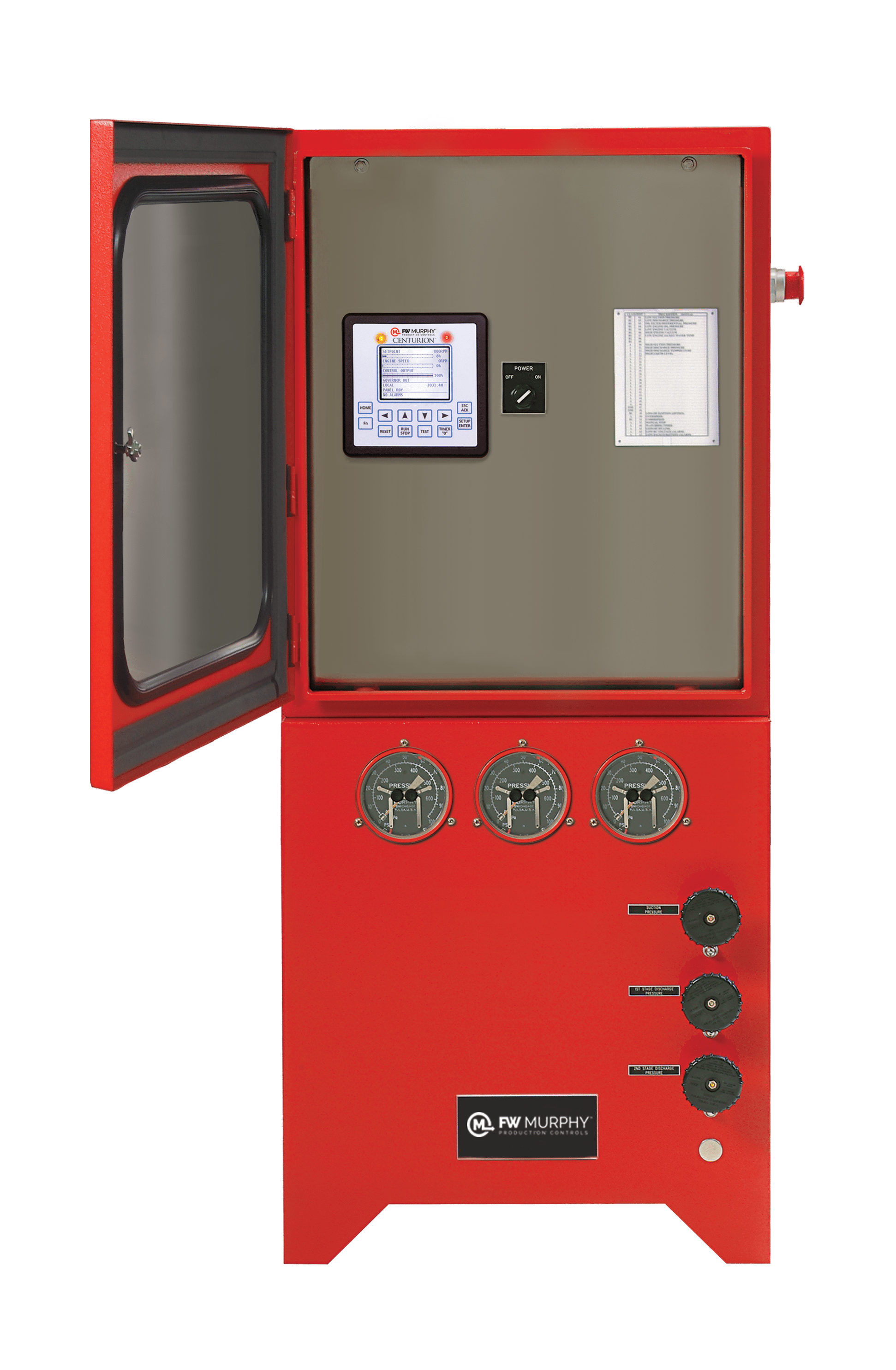

The Centurion PLUS Configurable Control Panel (C4) is the latest evolution in Murphy’s controller technology. This full-featured controller provides the stability of proven technology combined with the latest HMI touch screen for greater expandability and user interface. The Centurion Plus panel features custom application programming as well as full-time data logging and expandable communication capabilities.

The Series 1501 instrument is a microprocessorbased alarm, shutdown and control system with tachometer/hourmeter function. It annunciates in alphanumeric characters the protective device that has signaled an alarm or caused equipment shutdown. Information is called up and adjustments are made on a six-button keypad on the face of the unit. Configurations such as: Alarm or Shutdown Nomenclature, Preset Timers, and Tachometer Calibration can be made in the field. Murphy’s Series 1501 system has seven SPDT relays. On the standard model, the relays are assigned to the following functions: Lube, Crank, Ignition/Motor, Fuel Valve, Load, Alarm, Shutdown. The complete Series 1501 system consists of a head (monitor), sensor input terminal strip (two needed for 64 sensor models), 36 inch (914 mm) flat ribbon cable(s) for connecting the terminal block to the head/monitor, and a Class I, Div. 1, explosion-proof power supply. The Series 1501 system is powered from 120 VAC or 12 or 24 VDC. The head/monitor is rated intrinsically safe and includes a communication port: RS232 or RS485 (Modbus RTU slave). This port allows for remote control functions such as Start/Stop, Load/Unload, etc., and for access to Series 1501 registers.

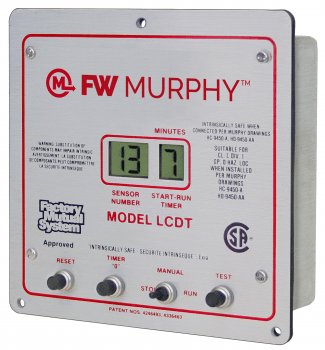

The LCDT Selectronic Tattletale system is a compact fault annunciator with an electronic alarm/shutdown control system. It was designed to protect engine-driven or motor-driven compressors and pumps. The annunciator indicates the sensor, and hence the parameter, that causes an alarm or shutdown. In addition, a means is provided for testing the operation of each sensor without initiating an alarm or shutdown. Employing a liquid crystal display, the LCDT system gives a digital reading of the tripped sensor and the lockout timer countdown. As the heart of the system, the basic annunciator component has two variations: the Model LCDT-NO, which accommodates normally open sensors, and the Model LCDT-NC, which accommodates normally closed sensors. These units are enclosed in an aluminum box having a brush finish. The LCDT system accommodates 47 sensor inputs, 15 of which may be locked out during start-up by the start/run timer delay. A separate power supply is provided with the model LCDT instrument. Power may be supplied by CD ignition, a 120 VAC line, or by 12 or 24 VDC battery.

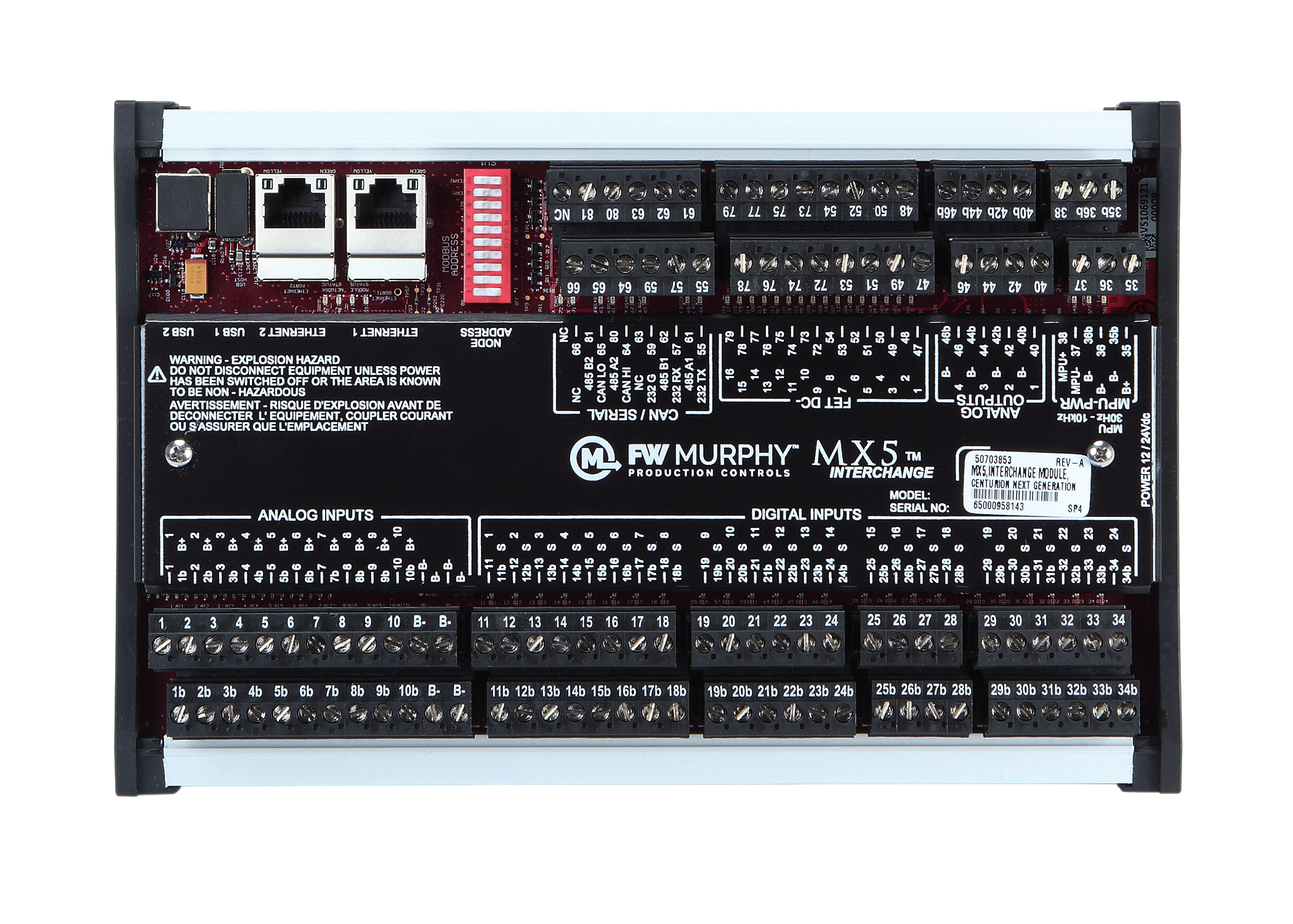

The MX4 expansion module provides temperature and frequency input capability to existing and future Murphy Controllers using CANBUS proprietary communications. Modbus® RTURS485/RS232 is also provided for other communication requirements. The MX4 module adds up to 18 thermocouples and 1 mpu. The MX5 expansion module provides input/output capability to existing and future Murphy Controllers using CANBUS proprietary communications. Modbus® RTU RS485/RS232 is also provided for other communication requirements. The MX5 module adds up to 24 Digital inputs, 8 Digital outputs, 10 Analog inputs, and 1 mpu. The MX5-A adds an additional 4 Analog outputs to the base MX5. The MX5-D adds an additional 8 Digital outputs to the base MX5. Any mix of MX-Series modules can be added to enable Digital and Analog I/O, and Thermocouple inputs for communication and monitoring by the master controller.

The Centurion PLUS™ Controller is a custom programmable control and monitoring system. Primarily designed for engine driven compressors, the Centurion™ PLUS is well suited for many control applications such as CNG control, Fire Pump Control, and many industrial control applications. Additionally, Murphy can custom design a control package to meet exact specifications for a variety of other applications. The Centurion PLUS™ continuously monitors input signals and set points and commands outputs to maintain proper operation. When an out-of-limits event occurs, the controller will stop, shutdown, or control equipment to change conditions. The Auto-Start capabilities of the Centurion™ PLUS allows for start/ stop based on parameters such as pressure set points or by digital signals. The Centurion™ PLUS allows for customer valve logic sequencing, purge cycle control, and many other logic applications. The Centurion™ PLUS can also provide complex calculation abilities such as rod load and temperature deviation. The Centurion PLUS™ provides real-time data via communications ports to a connected display and/or supervisory system. This advanced system offers multiple options for remote communications and operation including HMI’s, PLC’s, PC’s, and SCADA systems. The industry standard Modbus® RTU protocol means greater support for a wide variety of communication equipment including radio and satellite communications systems. Other communication options include Modbus TCP/IP, web page hosting, and data logging captured in standard CSV files uploadable through USB port.

The C4 Series Centurion Configurable Controller is a control and monitoring system. Primarily designed for engine/electric motor driven compressors, the Centurion is well suited for many control applications using standard configurations to save money and reduce training. Additionally, Enovation Controls can custom design a control package to meet exact specifications for a variety of applications. The Centurion continuously monitors input signals and set points and commands outputs to maintain proper operation. When an out-of-limits event occurs, the controller will stop, shutdown or control equipment to change conditions. The auto-start capabilities of the Centurion allow for start/stop based on parameters such as pressure set points or by digital signals. The Centurion provides real-time data via communication ports to a connected display and/or supervisory system. This advanced system offers multiple options for remote communications and operation including HMIs, PLCs, PCs and SCADA systems. The industry standard *Modbus® RTU protocol means greater support for a wide variety of communication equipment including radio and satellite communications systems.

Introducing the new Murphy VRU PRO. You know and trust the Murphy name for your compression needs. Now experience the VRU PRO, dedicated to controlling your system and designed specifically for vapor recovery applications. This Class I, Div. 2 hazardous area rated unit gives you the peace of mind required for your hazardous natural gas applications.

The TTD product is a solid-state fault annunciator and shutdown control system designed to protect engines, compressors and their associated equipment. The TTD model will accept 48 sensor inputs from normally open and/or normally closed sensors. Each of the 48 inputs can be configured for “Shutdown” or “Alarm Only”. Any input can be locked out by one of the two Start-Run timers, or configured as Class C, ESD or Ignore. The annunciator provides for both closing of a fuel valve and grounding of an ignition after a time delay. Incorporated in the TTD non-volatile memory:

•Run Hours/Elapsed Time Meter

•Last 10 Shutdowns with associated run hours

•Last 4 Alarms with associated run hours

•Selectable RS232/RS485 serial communications

•Selectable baud rates

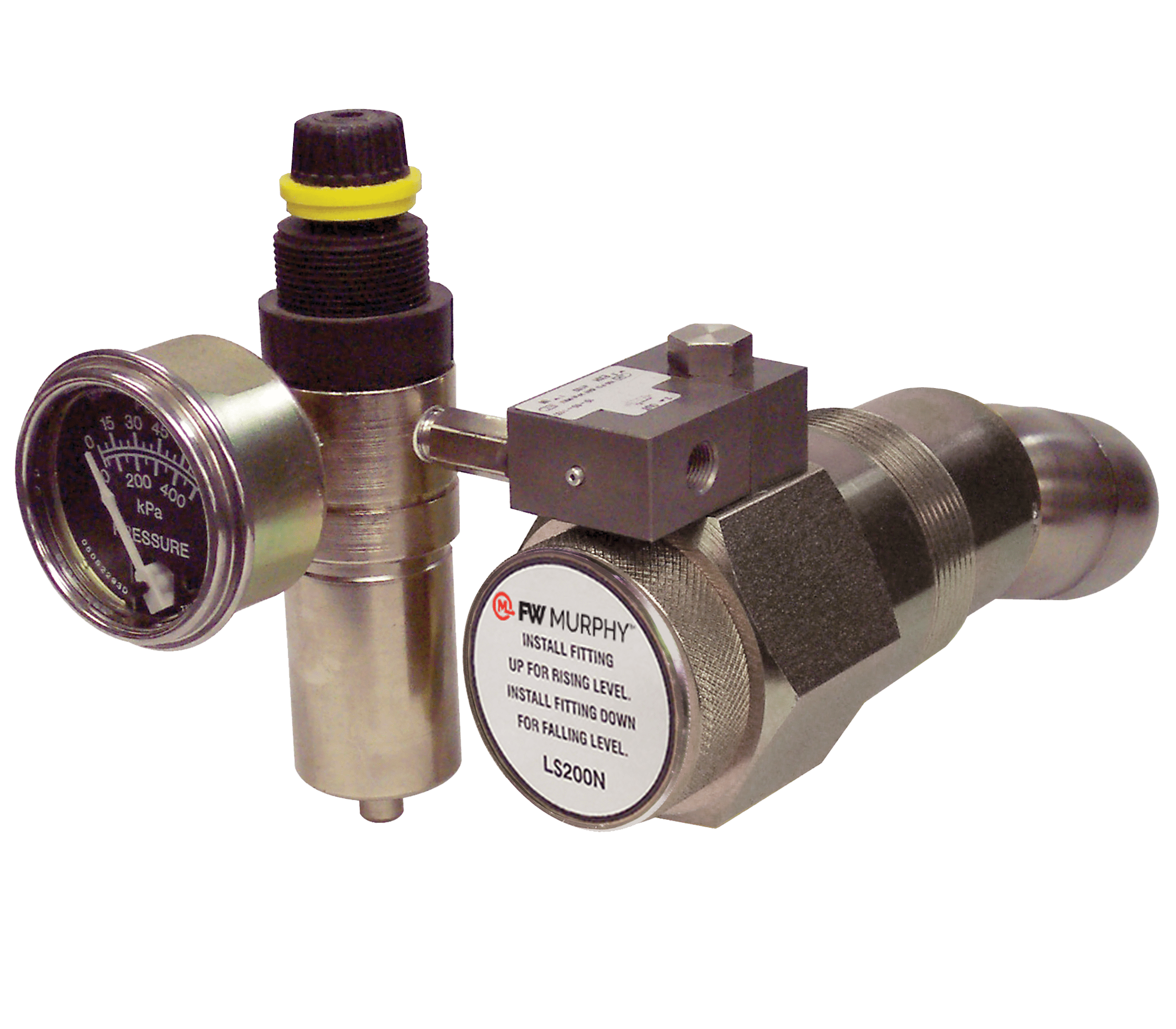

- Designed for harsh gas compressor scrubber applications

- 304 stainless steel float operates in 0.55 specific gravity and heavier fluids (see Table 1)

- LS200 series rated for 2000 psi (13.8 MPa) [138 bar] working pressure

- Electric and pneumatic models available

- More robust design

- All models screw directly into the scrubber or can be mounted via external float chamber

- Nickel plated body to provide enhanced corrosion protection

- Listed for Class I, Div. 1, Grp. C & D locations

- Canadian Registration Number 0F01476.2

- Stainless Steel models are available for corrosive atmospheres.

- Trip on rising liquid level only

The M2582-P and M5180-P are pneumatically controlled fuel shut-off valves that open and close automatically or semi-automatically. The pneumatic control pressure can be air, oil or gas. A manual lever aids in opening the valve when control pressure is insufficient. A gas escape vent, when properly vented and maintained, releases trapped gas from the valve after shutoff.